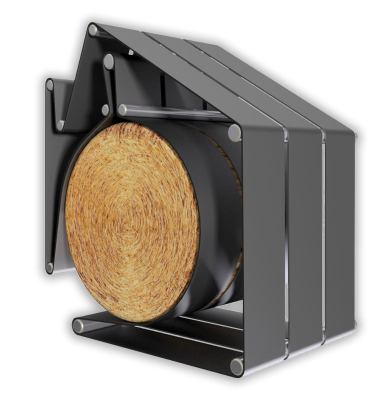

More durable, more powerful, more energy efficient: Using a special sewing process combined with a high-performance fabric, Artemis provides farmers and baler manufacturers with the Grizzly Splice, an extremely durable endless belt.

The heart of a modern round baler is the baling belt. It enables the farmer to highly compress hay, straw or silage. Farms around the world have been successfully using Artemis round baler belts for years.

Making products and processes more efficient, reliable and better are constant challenges in agricultural technology. Innovations in harvesting machinery are not always seen at first glance, but they show up in direct use in the field. The new Grizzly Splice round baler belt from Artemis exceeds previous requirements.

The name Grizzly Splice alone makes it clear: this is an extremely resilient endless belt with an exceptionally long product life. The experts at Artemis have developed a new manufacturing process with lower energy consumption and have achieved even greater strength, a longer service life and excellent service properties of the belts.

The vulcanization process of standard endless belts involves a great deal of effort. Thanks to the novel joining process of already vulcanized meter goods, the costly and energy-intensive vulcanization process can now be bypassed.

The new process makes it possible to design production sequences even more flexibly. At the same time, savings are achieved in energy and production capacities.

This solution was achieved by using a new type of manufacturing process for this product: the sewing process. The new manufacturing process is innovative because the way the belt ends are joined is mechanical, and at the same time the joining seam is optimally protected by being embedded in the rubber cover layer.

The structure of the endless belt and, above all, the special fabric enable excellent straight running with lower energy requirements; the fabric is highly flexible in the running direction and yet very stable in transverse direction.

Through field tests organized in-house by Artemis in cooperation with selected farmers, the company creates confidence for products and ideas.

Resource efficiency is an important factor in production. Thus, Artemis and every end customer of this new product contributes to more sustainability. On the customer side, the new belt splice ensures more longevity of the belt with a greener footprint at the same time, among other things through less energy consumption at the drive thanks to the dynamic base material.

Artemis has used its expertise in screening and conveying in harvesters, including the Silentium Drive (belts instead of steel chains in the inclined conveyor of combines), as well as customer feedback to create this new type of splice. It is unique in the market and — to the benefit of farmers and contractors — makes the belt much lower maintenance and more durable.

ARTEMIS Kautschuk- und Kunststoff-Technik GmbH

Rothwiese 4, 30559 Hannover (Germany)

Tel. +49 511 - 95928 0

Fax +49 511 - 95928 55

info@artemis-kautschuk.de

Arnold Jäger Holding GmbH

Artemis PC Pump Systems Ltd.

Transportbandenfabriek EA Broekema B.V.

Broekema Beltway USA, Inc.

Jaeger Envirotech India Private Limited

Jäger Gummi und Kunststoff GmbH

Jaeger Maritime Solutions GmbH

Jaeger Polska Sp. z o.o.

Jaeger Rubber & Plastics (Shenzhen) Ltd.

Jäger Umwelt-Technik GmbH

Jaeger-Unitek Sealing Solutions, Inc.

Spira Systems, Ltd.

Windgassen GmbH