The JÄGER Group develops versatile solutions from basalt

Nets and bags filled with stones or sand protect structures in the open sea – such as offshore wind turbines – from being washed out or weigh down submarine cables and pipelines.

The construction of offshore wind farms is challenging due to harsh environmental conditions. In the middle of the sea, wind turbine foundations and offshore high-voltage stations are installed. Products for scour protection and submarine cable covers in particular must not only be durable, but must also undergo numerous lifting cycles from filling with stones to precise placement under water.

The customer from the hydraulic engineering sector was looking for an environmentally friendly scour protection as an alternative to existing systems. Up to now there are similar products made of plastic, which are no longer an alternative for hydraulic engineering in the long term due to the introduction of microplastic into the oceans.

The customer turned to Jaeger Maritime Solutions GmbH, which has already made a name for itself in the industry with its innovative basalt bags as cable protection on offshore wind turbines, with the request for a sustainable solution.

Sustainable and robust alternative sought

The customer had already tested all the plastic solutions available on the market at that time, and all studies with the plastic alternative had already been initiated. Now Jaeger Maritime Solutions GmbH has to prove that a solution made of the natural material basalt is as robust as the plastic alternative. Just like the plastic version that has been used up to now, the construction is to have a single-point suspension for easy handling.

While the experts of the Jäger Group are working on the development of the new product, the customer has to learn which changes in working methods are necessary with the basalt product compared to the plastic net.

The customer‘s requirements are high, the net made of basalt fiber must be able to withstand being lifted, lowered and stacked safely 15 times. Initially, the first prototype cannot sustain these lifting cycles, and during the stacking test with five nets on top of each other, the high load of 32 tons of rock on the lowest net cannot be permanently maintained, so the Jäger developers optimize the design and material as well as the process. Further reinforcements within the product, a modified suspension and an optimized filling process finally led to the desired result on both sides.

Jaeger Maritime Solutions GmbH weaves tender bonds!

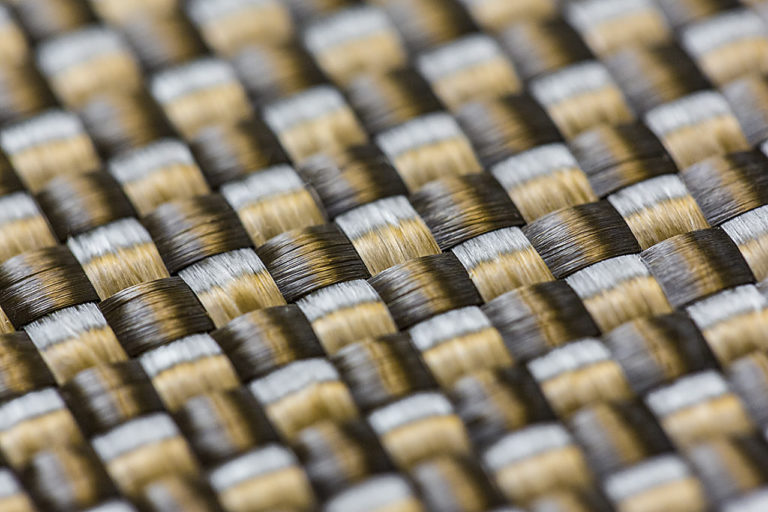

Stones are the answer! The nets are not only filled with stones, but also consist of stone. Or better said of basalt, which is processed into fiber.

In Germany, nets made of basalt fiber with an associated protective layer are woven for sustainable scour protection. The material is tested within the Jäger Group and the basalt net is subjected to regular 100% inspections on land. During the test of the net, the filling with eight tons, which can be done both on land and at sea, and the subsequent handling have to be checked. For this purpose, the experts of Jaeger Maritime Solutions GmbH coordinate closely with the client. After the test in Germany we went on to the on-site test. Together with the customer, extensive tests were carried out in Taiwan. The nets are closely inspected during filling, storage, loading onto transport vehicles and ships, and unloading in water. After the filled nets have met the safety requirements over several test days, the way is paved for environmentally friendly hydraulic engineering!

Jäger develops sustainable hydraulic engineering solutions

The result is an environmentally friendly solution made of basalt fiber that can be used in a variety of ways. The basalt nets can be used permanently or for short-term measures to secure offshore structures or to protect waters.

The big advantage: Due to the absence of plastic, Jäger products will continue to be suitable for use in hydraulic engineering in the future.

Load capacity

8 tons

Mesh size

Stone size

Diameter of the net

Temperature resistance

Jaeger Maritime Solutions GmbH not only produces nets from the innovative basalt yarn, but also basalt bags. The basalt bags have already been in use in hydraulic engineering since 2019. They can be filled with sand as well as with stones of up to four tons. Both basalt products can be installed as scour protection around the piles of offshore wind turbines. They are also used to fix and stabilize submarine cables or as bank reinforcement for inland waters.

Further basalt products are currently being tested.

Your Contact for Basalt Solutions:

Jaeger Maritime Solutions GmbH

Lohweg 1, 30559 Hanover (Germany)

Tel. +49 511 – 5358 0

Fax +49 511 – 5533 94

Arnold Jäger Holding GmbH

Artemis Kautschuk- und Kunststoff-Technik GmbH

Artemis PC Pump Systems Ltd.

Transportbandenfabriek EA Broekema B.V.

Broekema Beltway USA, Inc.

Jaeger Envirotech India Private Limited

Jäger Gummi und Kunststoff GmbH

Jaeger Polska Sp. z o.o.

Jaeger Precision Elastomers GmbH

Jaeger Rubber & Plastics (Shenzhen) Ltd.

Jäger Umwelt-Technik GmbH

Jaeger-Unitek Sealing Solutions, Inc.

Spira Systems, Ltd.

Windgassen GmbH