WE’LL BRING YOUR

HARVEST ON THE MOVE

We offer you a wide range of idlers and support rollers for conveyor belts in harvesters. With them you can transport your crop safely and smoothly. Our product range includes lightweight rollers as well as plastic, cast iron and rubber rollers with one or two ball bearings.

We are particularly proud of our specially developed idlers made of glass fiber reinforced plastic in combination with a rubber compound tread. The plastic has a noticeable effect in the lower weight, the elastomer ensures excellent running smoothness and provides the required elasticity for the idler.

We manufacture the lightweight rollers from these special impact-resistant and wear-free plastics:

These rollers are mounted either directly with a trunnion or with a hollow shaft.

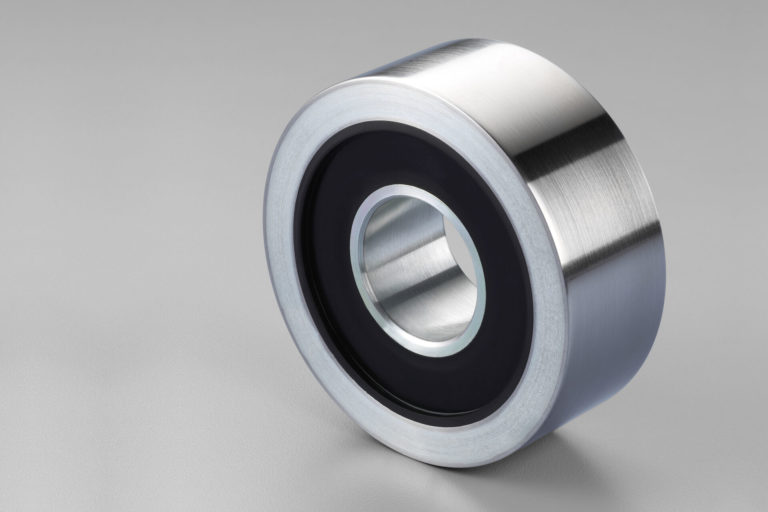

The plastic rollers are rubberized, have a low weight and are equipped with two ball bearings type 6005 2RS. They are available as standard with trunnion or open axle.

The cast iron rollers and rubberized rollers are equipped with two ball bearings type 6005 2RS as standard. Depending on the load, some rollers are offered with bearings of type 6206 2RS.

All plastic, cast iron and rubberized rollers have a three-part seal on both sides as standard to prevent contamination:

The axle on which the roller rotates can be an open axle (mounted with an M16 bolt) or a supporting journal with a hexagon on the head side and a nut with locking ring. As standard, the axles are designed for M16 threads, but other dimensions are also available.

For relubricatable systems, the axle can also be designed with a grease nipple. In this case 6005 bearings and/or 6206 bearings with grease filling between the two bearings and the open spaces are used. The standard metal caps and rings should then be replaced with convex metal caps and rings that allow less grease to pass through. The grease passes between the two bearings via a grease nipple at the head end of the axle. The convex metal caps and rings are secured by means of locking rings. The cast-iron shakers are pitch-bound and are mounted with an extended axle in the gearwheel run of the rod belt. The shakers are set in motion by the rod belt and the desired shaking effect is achieved by the triangular shape of the teeth. The universal rubber shakers and the triangular toothed rubber shakers are mounted below the rubber belt and are pitch-independent. Like the rollers, all shakers are mounted with two ball bearings and seals each.

Contact our experts:

Sales

Please select a valid form

– Netherlands –

Please select a valid form

– USA –

Please select a valid form

Arnold Jäger Holding GmbH

Lohweg 1

30559 Hannover (Germany)

Tel. +49 511 – 53580

Fax +49 511 – 553394

Management board:

Dipl.-Kfm. Marius Jäger

Dipl.-Ing Sebastian Jäger

Registercourt Hannover HRB 59983

DE 813 341 233

Arnold Jäger Holding GmbH

Artemis Kautschuk- und Kunststoff-Technik GmbH

Artemis PC Pump Systems Ltd.

Transportbandenfabriek EA Broekema B.V.

Broekema Beltway USA, Inc.

Jaeger Envirotech India Private Limited

Jäger Gummi und Kunststoff GmbH

Jaeger Maritime Solutions GmbH

Jaeger Polska Sp. z o.o.

Jaeger Rubber & Plastics (Shenzhen) Ltd.

Jäger Umwelt-Technik GmbH

Jaeger-Unitek Sealing Solutions, Inc.

Spira Systems, Ltd.

Windgassen GmbH