RELIABLE MATERIALS

FOR YOUR PRODUCTS

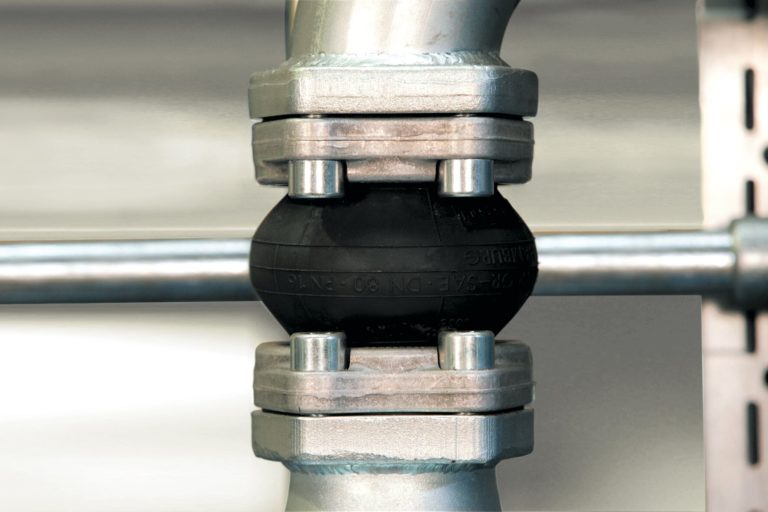

Rubber and plastic components for all areas of production

Nowadays, mechanical engineering requires materials and devices with highly flexible properties. No matter whether it concerns components for industrial companies, companies in the food industry, agricultural, chemical and laboratory technology or the commercial vehicle segment. Universal materials are required for insulation, sealing and damping.

High-quality components made of rubber and plastic have established themselves in the course of progress. In an increasingly networked and globalized world, customer and cost-oriented production is one of our core competencies. We focus on maximum efficiency with low energy consumption and the avoidance of plastic waste to the greatest possible extent.

As a producer, the JÄGER Group offers rubber and plastic components for the fields of mechanical engineering, plant construction, production technology and automation technology. We cover the entire range of polymers, thermoplastics, duroplastics and elastomers. They are characterized by their high wear resistance and chemical resistance. Our product range includes the following products:

For all parts, the high quality of the material and professional processing are decisive – under high pressure, even the smallest hole must be precise. All moulded articles, injection moulded parts and turned parts are tailor-made in product development to meet the application requirements of our customers. Thanks to the comprehensive expertise and know-how of our engineers, we are always at the cutting edge of technology.

Based on decades of tradition, we also take a step ahead in development. Experienced handling of materials and an experienced eye for requirements in practice as well as sensible modular systems are the basic prerequisites for sustainable solutions. We supply products for mechanical engineering that meet the very highest requirements. We master challenges and implement your requirements in a targeted manner!

We adapt the composition and Shore hardnesses of our rubber compounds exactly to your specific requirements. This ensures that the end products are resistant even at different temperatures or pressure elasticities and guarantees efficient processes in technology, mechanics of machines and constructions. Thanks to our in-house development laboratories, we are able to optimize the material compounds and the toolmaking in each case in a targeted manner. Among other things, injection moulding and blow moulding processes as well as rotational moulding are used. We work with thermoforming tools and press systems.

Close cooperation and trust in partnership with manufacturers of machine tools and other companies in the mechanical engineering and metal forming industries are important to us. In combination with our know-how in the field of development, manufacturing and production in plastics technology, this forms the best foundation for developing promising technologies and materials and thus producing high-quality products made of rubber and plastic for mechanical and plant engineering.

Progress makes it necessary to react quickly to changes — time and again, solutions must be found today for the problems of tomorrow.

The mechanical engineering industry is facing great challenges in these years. The world is moving closer together, companies are cooperating with each other across national borders, companies own plants and branches on other continents. This means that machines and all related parts have to function under the most diverse requirements and be both extremely durable and extremely flexible. Cost-effective production and reliable quality management are therefore the top priority.

It is precisely the components that laymen hardly see in machines at first glance that are often the decisive ones. It is not uncommon for precisely these parts to be made of the universal materials rubber or plastic. Progress makes it necessary to react quickly to changes – time and again, solutions must be found today for the problems of tomorrow.

As a strong partner for the mechanical engineering industry, we start with our large and comprehensive range of services wherever important rubber and plastic parts are needed for machines. Our claim is to provide individual, effective and efficient solutions for our customers.

With the help of specialised suppliers and access to the latest technology, we assume a cross-sectional function in the supply chain.

The added value concept of the JÄGER Group comprises a concept that is individually tailored to our clients. On request, we also offer this as a complete service, which includes numerous other service modules in addition to the components. The central element of this supply chain management is above all the individual consultation of our clients already during the selection of the moulding compound and the process sequence for each component.

The philosophy of the JÄGER Group includes the cross-company approach to create competitive advantages both for our own company and for our clients and suppliers. Process-oriented project management allows short development and production times – in the production if required also as a prototype, as a small series or as a series part as well as with the corresponding quantity scale in the calculation.

We offer our customers materials, components and assemblies optimally developed for the respective process, custom-made products and, if required, the appropriate logistics and an eBusiness concept for low reaction times in day-to-day business. This also includes supplier management based on a cooperative collaboration that has grown over the years. With the help of specialized suppliers, we have access to the latest technology and thus take on a cross-sectional function in the supply chain. Strategic partnerships also open up new business areas.

The development of new products is a continuous process. The focus is on safety and sustainability as well as efficiency and effectiveness. We are constantly working on the further development of our products. Our production materials include natural and synthetic rubber, silicone (liquid silicone) and polymer materials.

Our products must be able to withstand permanent loads and thus meet the requirements of different industries. These requirements include oil resistance, chemical resistance, cold resistance, heat resistance, waterproofness and elasticity of compression. As part of the development processes, our in-house development laboratories work closely with the Hanover-based German Institute for Rubber Technology to set standards. Our portfolio includes all forms of cellular rubber (natural rubber, EPDM, chloroprene rubber and nitrile rubber). To ensure that our products meet your specific requirements, our specialists regularly check the quality and properties of the materials and products.

- Germany -

Please select a valid form

- Germany -

Please select a valid form

- USA -

Please select a valid form

Arnold Jäger Holding GmbH

Lohweg 1

30559 Hannover (Germany)

Tel. +49 511 – 53580

Fax +49 511 – 553394

Management board:

Dipl.-Kfm. Marius Jäger

Dipl.-Ing Sebastian Jäger

Registercourt Hannover HRB 59983

DE 813 341 233

Arnold Jäger Holding GmbH

Artemis Kautschuk- und Kunststoff-Technik GmbH

Artemis PC Pump Systems Ltd.

Transportbandenfabriek EA Broekema B.V.

Broekema Beltway USA, Inc.

Jaeger Envirotech India Private Limited

Jäger Gummi und Kunststoff GmbH

Jaeger Maritime Solutions GmbH

Jaeger Polska Sp. z o.o.

Jaeger Rubber & Plastics (Shenzhen) Ltd.

Jäger Umwelt-Technik GmbH

Jaeger-Unitek Sealing Solutions, Inc.

Spira Systems, Ltd.

Windgassen GmbH